OWN MANUFACTURING, SUSTAINABILITY AND INNOVATION: THE KEYS TO OUR GARDEN PRODUCTS

Our origins as a manufacturer make us place great value on the importance of the quality of our products and our long-term commitment to our customers. For this reason, and in line with our sustainability strategy, we set very high standards for our product portfolio, both those manufactured in-house and those sourced from external suppliers.

Having our own manufacturing site contributes very positively to reducing energy consumption and carbon footprint, while allowing our teams to collaborate closely throughout the entire creation process. This proximity and non-dependence on external suppliers gives us flexibility, high availability and control, and thus a high capacity to create durable and responsible solutions.

WE ARE MANUFACTURERS

In our own manufacturing center, we produce KM.0 concealment systems. We also have a zero waste policy. Our extensive experience allows us to innovate and offer superior quality products.

CULTURE OF SUSTAINABILITY

A common principle that starts from conception and ends with the reuse or recycling process of our products.

R&D, AT THE HEART OF INNOVATION

Innovation is in the Group’s DNA. Constant improvement stems from our vocation to satisfy our customers.

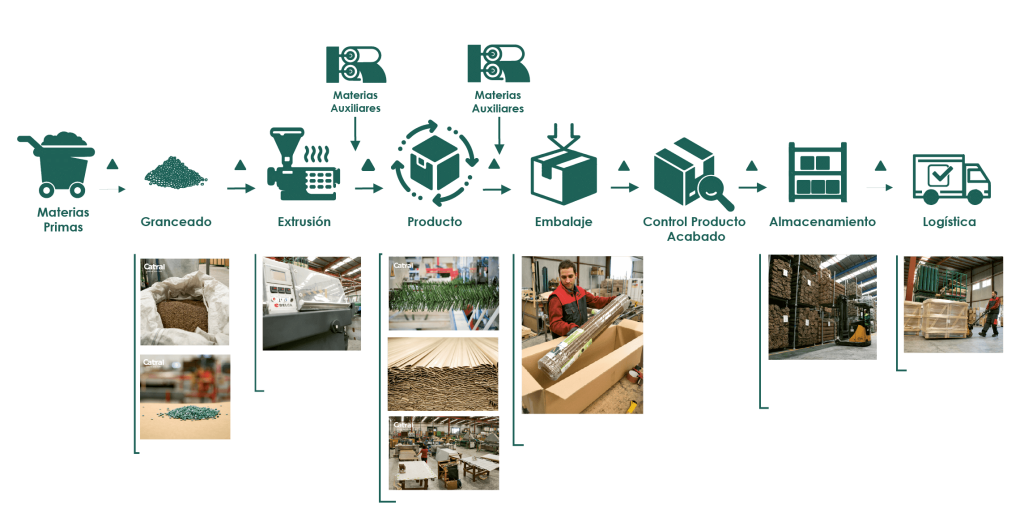

LEARN ABOUT OUR MANUFACTURING PROCESS

Discover the manufacturing process in our own production plant in Alicante (Spain). Equipped with exclusive machinery for the treatment of PVC and recycled PVC, we continue to invest in research, development and production in order to lead the market of exterior fittings and decoration.

Zero Waste Policy

Our production and logistics center has a zero waste policy. Thanks to this, we have renewed for the third consecutive year the Saica Natur “From Waste to Resources: Zero to Landfill” seal, certifying that 98% of the waste generated is recovered through recycling or reuse.

OUR OWN MANUFACTURED ICONS

LOP Screening

In our commitment to provide sustainable solutions for outdoor spaces, we present the LOP range of products. Manufactured in our European production center in Catral (Spain).

LOP eco-friendly wicker has been a true revolution in the market for sustainable garden products. The innovative material composition is designed to reuse waste and reduce the impact on the planet.

Since 2012, we have managed to recycle more than 500,000 kg of organic material for its manufacture, thus reaffirming Catral Group’s commitment to the protection of our environment.

PVC Screening

We work every day to redefine the future of our products towards a more ecological path. As a result of this work, we have managed to maintain the quality of our PVC reed, manufacturing it with 30% recycled materials.

The RECYCANE reed is the only enclosure with recycled compound in the market. In this way, in Catral, we continue to reduce the consumption of virgin resins for the manufacture of new solutions for the market, respecting two of the main values of Catral Group: in-house manufacturing and sustainability.

Artificial Hedges

Our artificial hedges, manufactured entirely in Catral, are the result of rigorous research and development. Our team of experts is constantly working to create innovative solutions that combine aesthetics, resistance and privacy. Thanks to our own manufacturing, we control every stage of the process, from the selection of raw materials to the final product, guaranteeing maximum quality and compliance with the highest industry standards.

Our commitment to innovation translates into durable, weather-resistant and highly customizable products.

Natural Screening

The Coconatur hedge is the first natural hedge manufactured 100% in our production center in Catral. Its biodegradable coconut fibers are woven with galvanized metal wire on the inside and plasticized on the outside, thus providing a high density between its rods and, therefore, a high level of concealment.